Induction Heating Machines

Induction Heating Machine use electromagnetic fields to heat materials efficiently and uniformly. A specialized induction heating machine for a beginning line is designed to streamline production processes by offering quick setup times, precise temperature control, and energy efficiency.

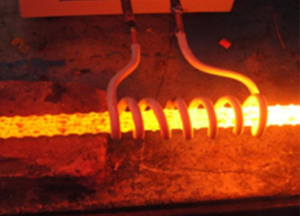

End bar Heating (induction heating machines

End bar heating with super audio machine refers to a process commonly used in industrial applications to heat the ends of metal bars rapidly and uniformly. This heating method often utilizes induction heating technology, where high-frequency (typically in the super-audio range, around 10-50 kHz) alternating currents create a magnetic field, inducing heat directly in the metal. Induction Heating Machines Manufactures copper bar and steel end bar heating. and best Technology in haryana.

U Bolt Making (Induction Heating Machines

The use of an induction heating machine in the U-bolt manufacturing process is primarily involved in the heating , phase, particularly. When producing U-bolt from thicker or high-strength materials. induction heating helps ensure efficient uniform heating for the bendind process, reducing the risk of material defects and improving precision. Here’s how the induction heating machine features:

Who Are WE

Malhotra Technologies Established in 2007, Malhotra Technologies (INDUCTION MASTER) is a reputed company that manufactures and supplies a broad assortment of (INDUCTION HEATING MACHINES) induction-hardening machines, high-frequency induction heaters, medium-frequency power heaters, UHF induction heaters, annealing machine, sintering machine, electroplating rectifiers, heat-treatment machine, and brazing machine. They also supply products like 15 series induction heaters, 25 series induction heaters, 35 series induction heaters, 70 series induction heaters, medium frequency power heaters, melting machine frequency power heaters,s and forging furnace frequency power heaters. These items are developed using high-quality raw materials procured from retailers following international norms. KNOW MORE.

Why Choose Induction Heating Machines

Induction Heating Machines use large hardening workpiece, tempring, cooling, solid design, high frequency induction heating machines fullyautomatic.

Why choose us

Malhotra Technologies Established in 2007, Malhotra Technologies is a reputed company that Manufactures and supplies to Induction heating machine.Journey of Naveen Malhotra.

Induction Heating Machines (faq)

Usage :

>Thermoforming (hot-forging, heat penetration formation, hot rolling

>Brazing (brazing, hot cooperation, hot painting

>Heat Treatment (quenching, Annealing, hardening, etc.)

>Melting (melting for gold, copper, stainless steel and other metal materials )