Ultra High Frequency Induction Heating Machine(UHF) is specialized heater that mostly used for processes like metal heat treat, metal and copper brazing, solid welding point, and heat treatment, where precise, limited to a small area heating is required. It is applied to the welding and inserts used in metal glass manufacturing as well as electric appliance and electronics industries, non-contact brazing of internal parts of small-size relays, high-pressure refrigerating parts, headwear decorations, metal ornamental articles and art wares.

Like Malhotra Technologies Manufacturing Of Induction Heating Machine

MAIN FEATURES

1) This equipment adopts the IGBT inverter circuit in parrallel connection, which has is high load adaptability.

2)

The comprehensive full load design is available for-24 hours continuous operation.

3)

The digital phase locked realizes following frequency automatically.

4) design in modules, It is installed facility and use conveniently without debugging.

5) The perfect protection function, insuring the reliability and easily maintaining of the equipments.

6) The technique of converting frequency by reasonance promotes efficiency of whole equipment by over 95%.

7) Economy and environment protection. It can replace of the gas/coal/electronic tube induction heating machine.

Key Features and Working Principal

1. High-Frequency Range:

Ultra-high frequency induction heating usually works at frequencies around 50KHz to 1.1MHz, often in the range of 1 MHz to several tens of MHz These frequencies offer faster heating and finer control over the heating process.

2. Electromagnetic Induction:

The Machine works by generating a high-frequency alternating current (AC) that passes through a coil, generating a fast be indecisive magnetic field. When a conductive material (like metal) is placed within in this magnetic field, it induces electric currents (called eddy currents) within the material. these eddy currents cause resistance heating raising the temperature of the material.

3. Precise Control:

The high-frequency waves ensure that the heat is generated quickly and only in the surface or a thin layer of the material, reducing thermal gradients and ensuring uniform heating over a localized area.

Top 4 Applications

1. Metal Hardening: Localized heating to harden specific areas of a metal part.

2. Brazing & Soldering: For joining metal parts without the need for a direct flame.

3. Surface Treatment : To alter the surface properties of metals, such as improving wear resistance.

4. Melting: For small quantities of metal that need to be melted quickly for casting or molding

Top 4 Advantages

1. Speed: Ultra high frequency heating machine is faster than tradtional heating methods, reducing cycle times.

2. Precision: It allows for localized, highly controlled heating, which is ideal for applications requiring specific temperature zones.

3. Energy Efficiency: It minimizes energy waste since the heat is generated directly in the material, rather than through a medium like gas or electricity in conventional heaters.

4. Reduced distortion: Because heating occurs quickly and in a localized area. thermal distortion of materials is minimized.

Consideratons:

1. Material Compatibilty: The material being heated needs to be electrically conductive(typically metal) Non-metallic materials cannot be heated using induction.

2. Cooling: High-frequency induction heaters generate a lot of heat, so proper cooling mechanisms (such as water or air cooling)are needed to prevent overheating of the machine and components.

3. System Cost: ultra-high-frequency induction heating machines can be more expensive due to the specialized components and the high-frequency generators used.

What We Do

Malhotra Technologies Established in 2007, Malhotra Technologies (INDUCTION MASTER) is a reputed company that manufactures and supplies a broad assortment of (INDUCTION HEATING MACHINE) induction-hardening machines,Induction Forging Machine, high-frequency induction heaters, medium-frequency power heaters, Ultra High Frequency induction heaters, annealing machine, sintering machine, electroplating rectifiers, heat-treatment machine, and Induction brazing machine. They also supply products like 15 series induction heaters, 25 series induction heaters, 35 series induction heaters, 70 series induction heaters, medium frequency power heaters, melting machine frequency power heaters,s and forging furnace frequency power heaters. These items are developed using high-quality raw materials procured from retailers following international norms.Special Purpose KNOW MORE.

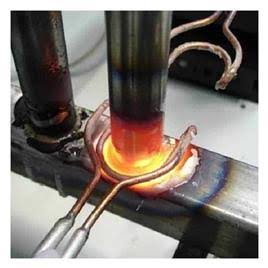

INDUCTION BRAZING MACHINE

Brazing is a fusion and solidification process which refers to the use of magnetic field induction heating to make the temperature of metal materials junction reach the metling point of solder, or the temperature of metal material to reach between nonmetallic material. Its main features: good working conditions, high efficiency, good tightness and performance after brazing, simple operation and high safery, no pollution, and high fire resistance.

INDUCTION FORGING MACHINE

Hot forming, hot forging, diathermy molding, hot rolling, hot upsetting and red stamping are all used induction heating machine to make the work-pieces nearly have the same temperature on surface and internal. then punching into required shape. which mainly adopt electromagnetic induction and heat conduction principal.