Induction Brazing Machine

What is an induction Brazing machine

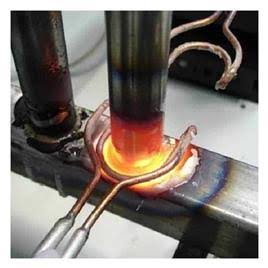

Induction brazing machine is an industrial heating machine. This machine is use two type of Industry (1 Any industry of add solder connection. 2 Do not add solder connection). Induction brazing machine using induction heating to join metal component and copper, using a filler material (braze alloy) to reach a permanent bond. Induction brazing machine produce the alternating magnetic field through induction coil after induction equipment outputs high-frequency current to make the work piece heated quickly.

Any deal by India mart site.

Applications

Any Industry of add solder connection.

Such as: cutting tools (turning tool, milling cutter, woodworking tools, serrated blade, shoe materials, diamond tool, deep hole drilling, drilling, etc). Faucets, bathroom accessories, showers, coal drill, drill bit, terminal blocks, furniture fittings, refrigeration equipment, pad tube, heating plate, egg beater, lighting accessories, such as branch distributor, bicycle up and down the fork iron, copper pieces, aluminum, stainless steel brazing.

Do not add solder Connection.

Such as: computer radiator core and copper core, motor rotor and shaft, horn net preparations, hanger hook, copier carbon brush melt, aluminium-plastic pipe the compound preparations kettle, tool shank cure, tableware curing rubber handle, battery pole ear forming, aluminium foil sealing, etc.

Brazing Machines Models

Ultra High Frequency Induction Heating Machine

1. This machine is available in small size, light weight, low failure rate and conservation of energy power 70%.

2. That brazing machine feature the solid welding point which is pleasing and delicate in appearance. brazing machine display show over-current, over-voltage, water shortage and phase missing can provide higher digital control system and durability.

3. Ultra high frequency series = MTCG-3kw to 100kw applicable.

Induction Brazing Machine is a specialized device heats electrically conductive materials by using electromagnetic fields. brazing is a fusion and solidification process which refers to the use of magnetic field induction heating to produce the temperature of metal materials junction reach the melting point of solder, or the temperature of metal material to reach between non-metallic material.

here’s main features: good working conditions high efficiency, good tightness and performance after brazing, simple operation and high safety, no pollution, and high fire resistance.