INDUCTION HEATING MACHINE

Characteristics of Induction Heating Machine

A. Fast Heating: The quickest rate of heating is less than 1 second, and the rate of heating is available for adjustment and control.

B. Widely applicable: It can be used to heat various metal parts (can replace the removable induction coil for different shapes).

C. Low Power Consumption: Compared with traditional vacuum tube high-frequency machines, the heat efficiency can be over 95%.

D. High Effectiveness: It is applicable to control the temperature for heating work pieces that have such features as uniform heating, fast warming, and limited oxic horizon.

E. High Efficiency: It can work continuously for 24 hours for a comprehensive full-load design. And with the function of automatic setup. Just one person can operate it which can save the process.

F. Small size and lightweight: It weighs only several dozen KGS and with a small size that can save space in the workshop and can be moved conveniently.

G. Easy operation: CNC design, easy installation, and simple operation that you can learn to operate within several minutes. It can be started to perform heating operations on condition that water and power supply are available.

H. Environmental protection: it is free of any noise, exhaust gas, and dust that can provide a much better environment for the workers than conventional heating with such fuels as coal, gases, and oil.

Type of Induction Heating Machine

Our Induction Heating Equipment Divided According to Output Frequency

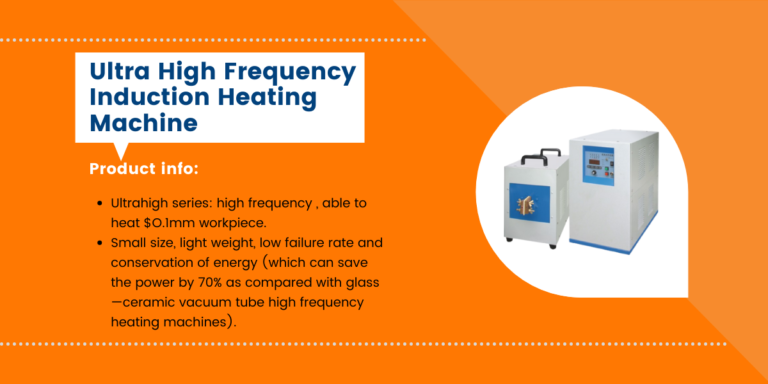

1. Ultra high frequency(MTCG) series: frequency 100KHz-1.1MHz.

2. High frequency(MT) series: frequency 30KHz-100KHz.

3. Super audio frequency(MTC) series: frequency 10KHz-30KHz.

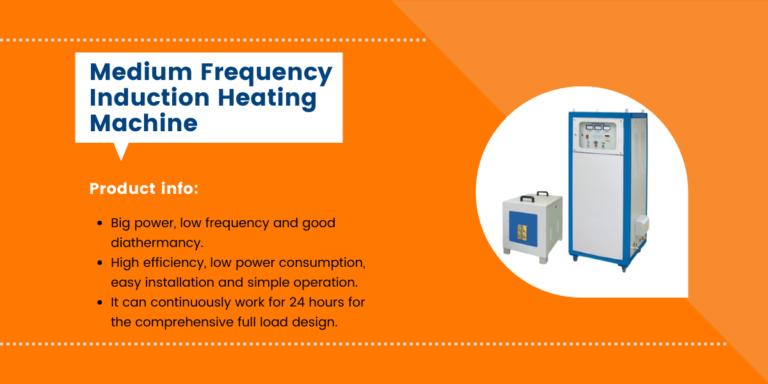

4. Medium frequency(MTTZ) series: frequency 0.5KHz-20Khz.

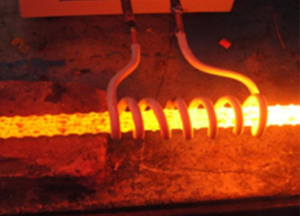

In The Old Times All Forging Processes Were Processed with Flame, Costly Batch or Furnace.

But Today Technology Has Solved This Problem.

MALHOTRA TECHNOLOGIES Has Made Forging Process Safe and Easy with The Help of Our Own INDUCTION HEATING MACHINE Feature.

INDUCTION FORGING MACHINE Turns Material into Heat Without Flame or Furnace.

FIND INDUCTION HEATING MACHINE NEAR BAHADURGARH (MALHOTRA TECHNOLOGIES)

The End bar heating process is an Industrial Technique used to selectively heat the ends of metal bars.

U-bolt heating is used in many industrial applications, especially in assembly and disassembly processes. U-bolt using

round bar heat penetration, hot forging for pontin, hot forging for copper stick,

An Induction brazing machine joins two metals by induction heating.

Using present-day flameless technology, Induction brazing machine

Creates a magnetic sphere to heat the metals.

Compared to brazing without a traditional torch, this machine is more stable, repeatable and also automatic. Induction heating machine

.

Its main features: good working conditions, high efficiency, good tightness and performance after brazing, simple operation and high safety, no pollution, and high fire resistance.

Who Are We

Malhotra Technologies Established in 2007, Malhotra Technologies (induction master) is a reputed company that manufactures and supplies a broad assortment of induction heating machine types induction-hardening machines, Induction Forging Machines, high-frequency induction heaters, medium-frequency power heaters, UHF induction heaters, annealing machine, sintering machine, electroplating rectifiers, heat-treatment machine, and Induction brazing machine. They also supply products like 15 series induction heaters, 25 series induction heaters, 35 series induction heaters, 70 series induction heaters, medium frequency power heaters, melting machine frequency power heaters, and forging furnace frequency power heater Technologies. These items are developed using high-quality raw materials procured from retailers following international norms. Induction Heating Machine, (Applications)

A super audio frequency induction heating machine is a specialized heating device for fast heating, high efficiency, low power consumption, easy installation, and simple operation.

Recommend Usage:

Hot Forging, Quenching, Stainless steel annealing, forging.

ultra high series: high frequency, able to heat 0.1mm workpiece. small size, light weight, low failure rate and conservation of energy(which can save the power by 70% as compared with glass-ceramic vacuum tube high frequency heating machines).

Recommend Usage:

Brazing, Heat Treatment, Forging, Heavy duty component, etc.

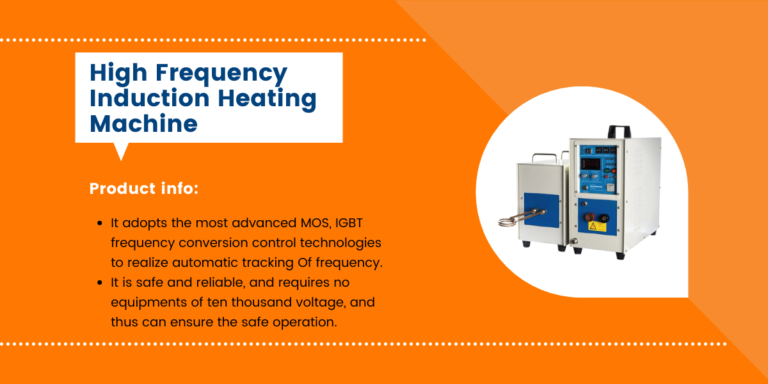

High frequency induction heating machine this machine heats up the metal with its magnetic power.

The machine which is mostly used in industry works automatically as well as manually

Recomment Usage:

Brazing, forging, Hot Cooperating, Melting, Annealing for Stainless steel goods.

How are we different?

Experienced

We are in the market with 15 years of experience

Quality-Conscious

We are known for the best quality in the market.

Core strength

Our Core Strength is our Best, Dedicated, and Hardworking Team.

Awards & Certificates

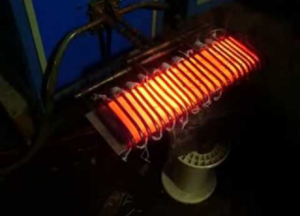

Induction heating is a process in which the machine transmits heat through its electromagnetic field which heats the material.

Induction heating machine transmits heat through copper coil.

This is a new technology machine used in industry which is used for heating purposes today.

In the old times metal was heated using flame or furnace but today induction heating machine has made this work easy, safe and automatic.

Malhotra technologies has been growing industrial products for the past 15 years with the special features of its machines.

If you are from automotive, electronics, metal, aerospace industry you need induction heating machine.

Induction heating machine saves energy, reduces cost, improves product quality and work is also done quickly. Your investment in induction heating machine increases the growth of your industry. Today induction heating machine is famous all over the world. And its automatic and manual system has made people’s work easy.

2. When precision, speed and quality are critical.

3. When safety and environmental concerns need to be addressed.

4. When the application involves delicate or complex components requiring localized heat.

Note- If you’re evaluating induction heating for a specific project or industry, I can provide tailored advice!