What is High Frequency induction heating machine

A High-frequency induction heating machine uses a magnetic field to induce current in a conductve material, producing heat. unlike traditional methods, induction heating is contactless, fast and highly targeted.

The key components include:

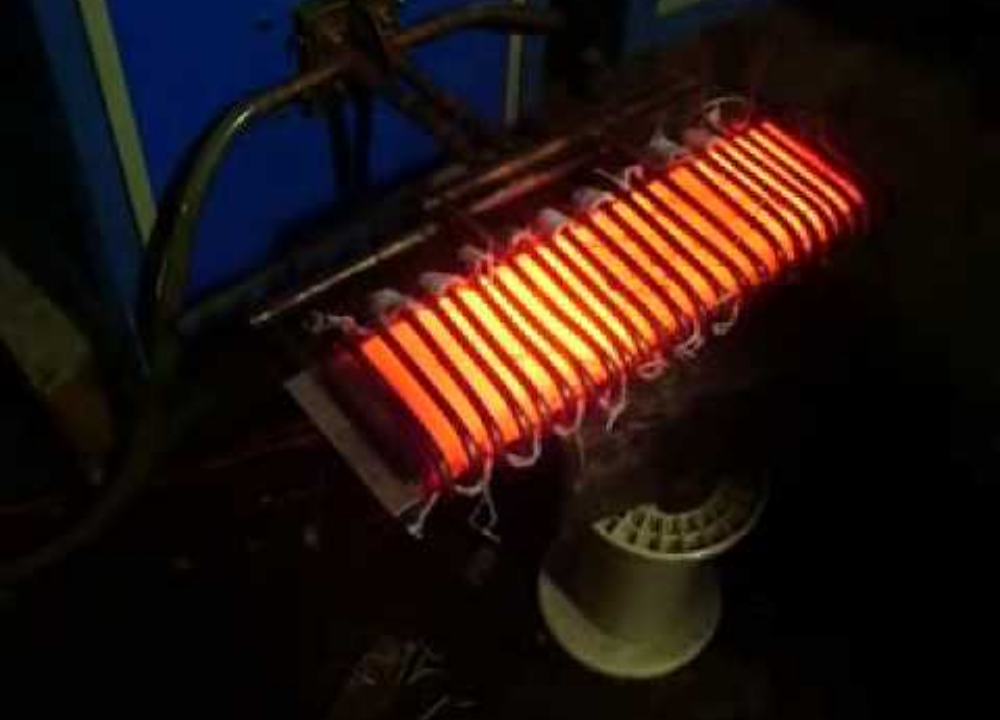

_ Induction Coil : Generates the magnetic field.

_ Power source: Supplies the required high-frequency current.

_ Cooling System: Prevents overheating of the equipment

Main Feature:

2. It has the constant current and power control function, which can significantly optimize metal heating process, realize the high efficient and fast heating and bring into play the superior performance of the products.

3. About ten types fault protection and display of over-current, over-voltage, water shortage and phase missing can provide higher reliability and durability.

4. It is safe and reliable, and requires no equipments of ten thousand voltage, and thus can ensure the safe operation.

5. It is available for infrared temperature measurement, which can realize the automatic control of temperature, improve the heating performance and simplify the manual operation.

High-frequency Induction Heating Machine for forging

Overview

Hot forming, hot forging, diathermy molding, hot rolling, hot upsetting and red stamping are all used induction heating machine to make the work-piece nearly have the same temperature on surface and internal. then punching into requied shape, which mainly adopt electromagnetic induction and heat conduction principal.

Application

Fasteners, hardware tools, automobile and motorcycle accessories, rigging, pipe fittings, twist drill, atlas, table, mould parts, standard parts, handicraft, machinery parts, brass lock, lock, rivets and other hardware and metal accessories.

Forging application:

bar end heating, bar forging furnace, bar forging, bar heating, bar hot forging, bar induction heating, bolt forging, carbon steel forging, copper bar forging, hot forging, copper plate heating, round bar forging, steel bar forging, steel billet induction forging, square iron diathermy, nut forging.

Why choose high frequency heating machine

Why choose high frequency heating machine Put in a high-frequency induction heating machine warrants dependability, solidity, and compliance in a selection of industrial applications. With increasing importance on sustainability and good organization, these machines are flagging the way for smart manufacturing processes.

Who Are We

Malhotra Technologies Established in 2007, Malhotra Technologies (INDUCTION MASTER) is a reputed company that manufactures and supplies a broad assortment of (INDUCTION HEATING MACHINE) induction-hardening machines,Induction Forging Machine, high-frequency induction heaters, medium-frequency power heaters, UHF induction heaters, annealing machine, sintering machine, electroplating rectifiers, heat-treatment machine, and brazing machine. They also supply products like 15 series induction heaters, 25 series induction heaters, 35 series induction heaters, 70 series induction heaters, medium frequency power heaters, melting machine frequency power heaters,s and forging furnace frequency power heaters. These items are developed using high-quality raw materials procured from retailers following international norms.Special Purpose KNOW MORE.