SUPER AUDIO FREQUENCY HEATING MACHINE

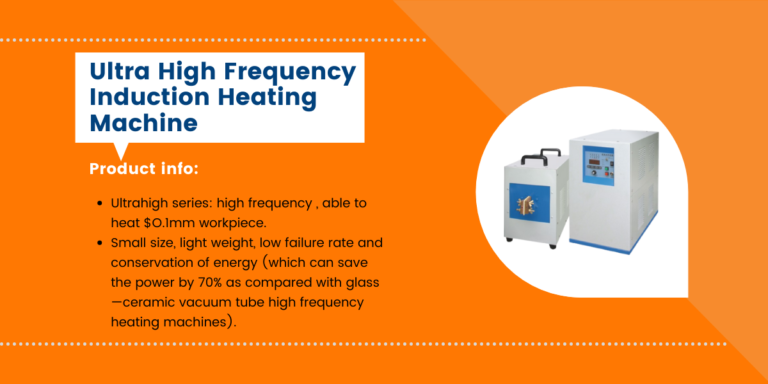

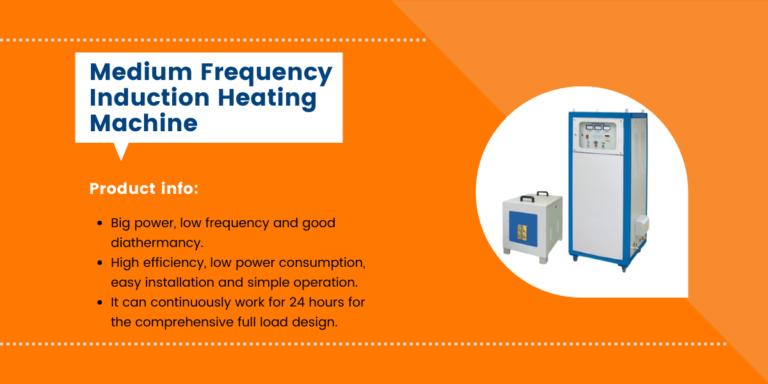

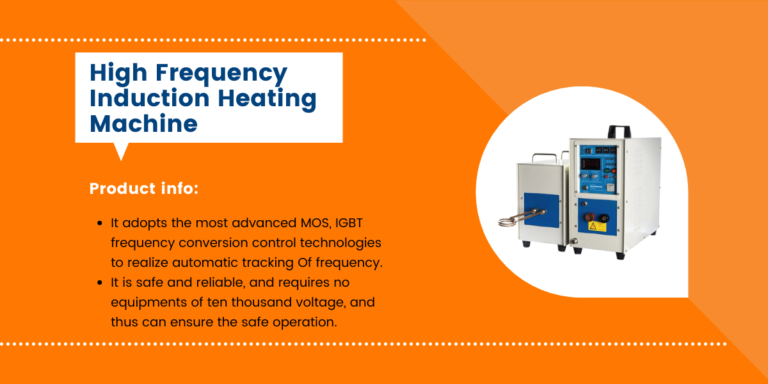

A SUPER AUDIO FREQUENCY INDCUTION HEATING MACHINE(SAFIH) is a specialized devices used for heating materials, typically metals and using electromagnetic induction at super audio frequencies(often around MTC-30kw to MTC-200kw). A super audio frequency indcution heating machine utilizes high-frequency elctromagneic fields to generate heat within conductive materials. Here some key aspects of Malhotra Technologies

Super Audio Frequency Heating Machine

Induction heating is a specialized method where heat is generating with in a material by electromagnetic induction. That means to produce the alternating magnetic field through induction coil after induction-heating equipment outputs high-frequency current to make the work piece heated quickly.

While Super Audio induction heating typically operates in the audio or medium-frequency ranges (around MTC-30kw to MTC-200kw), This increased frequency brings about distinct advantages in terms of heating speed, precision, and control. By using higher frequencies, the energy can be concentrated more effectively within the material being heated, leading to more efficient results.

Super Audio Frequency Heating Machine: Revolutionizing Industrial Heating Solutions

In today’s fast-paced industrial landscape, the demand for precision, efficiency and stability in manufacturing processes is greater than ever before. One of the major technologies developed to meet these needs is direct frequency direction heating machines. These innovative technologies are transforming industries from metals and automotive to electronics and manufacturing, ushering in a new era of heating solutions that are faster, more energy-efficient and more efficient than traditional methods.

In this blog, we will learn what super audio frequency indexing is, how it works, and how many benefits it brings to industries around the world..

SAF induction heating is used in a variety of industries, offering benefits such as faster cycle times, lower energy consumption and better product quality. Some common applications include Is:

2. Brazing and soldering

3. Forging and Casting

4. Heat treatment of components

5. Wire and cable heating

INDUCTION ANNEALING MACHINE

An induction annealing machine is a part of industrial equipment designed for annealing Heat method, that is heat treatment system used to modify the properties of materials (typically metals) by Induction heating them to a specific temperature and then allowing them to cooling system. The purpose of annealing is a lot to relieve stresses, improve quality, and improve the microstructure of metals or alloys.

How Does work:

Induction annealing used electromagnetic induction to heat the material. In this method, an alternating current(AC) passes through a coil, generating a wavering magnetic field. When the material is located inside this magnetic field, it makes electrical currents (eddy currents) in the material itself. These currents generate heat in line for material area. A super Audio Frequency heating machine the specific models applicable in the stainless steel Industry for Annealing.

Induction Forging Machine

Hot forging, diathermy, melding, hot rolling, hot upsetting and red stamping are all used induction heating machine to make the work-pieces nearly the same temperature on surface and internal. then punching into required shape, which mainly adopt electromagnetic induction and heat conduction principle.

Applications

Fasteners, hardware tools, automobile and motorcycle accessories, rigging, pipe fitings, twist drill, atlas, table, mould parts, standard parts, handicrafts, machinery parts, brass lock, lock, rivets and other hardware and metal accessories.