Induction Annealing Machine

An induction annealing machine is a part of industrial equipment designed for annealing Heat method, that is heat treatment system used to modify the properties of materials (typically metals) by Induction heating them to a specific temperature and then allowing them to cooling system. The purpose of annealing is a lot to relieve stresses, improve quality, and improve the microstructure of metals or alloys.

Related of Induction Annealing Machine by Malhotra Technologies

Copper Wire Annealing

Copper wire annealing take in heating copper wire to a specific temperature and then cooling the situation in professionally. This heat treatment method adjusts for copper’s crystalline structure, falling the hardness and increasing its ductility. After the result, the copper wire becomes more flexible, less brittle, and easier to handle or process further.

Annealing copper wire is usually complete by controlled temperature methods, like induction heating and furnace annealing, dependent on the wire’s size and projected use. This method makes sure the wire is best for applications that require consistent quality and high performance, for instance electrical and electronic devices.

Induction heating Machine Working Principal

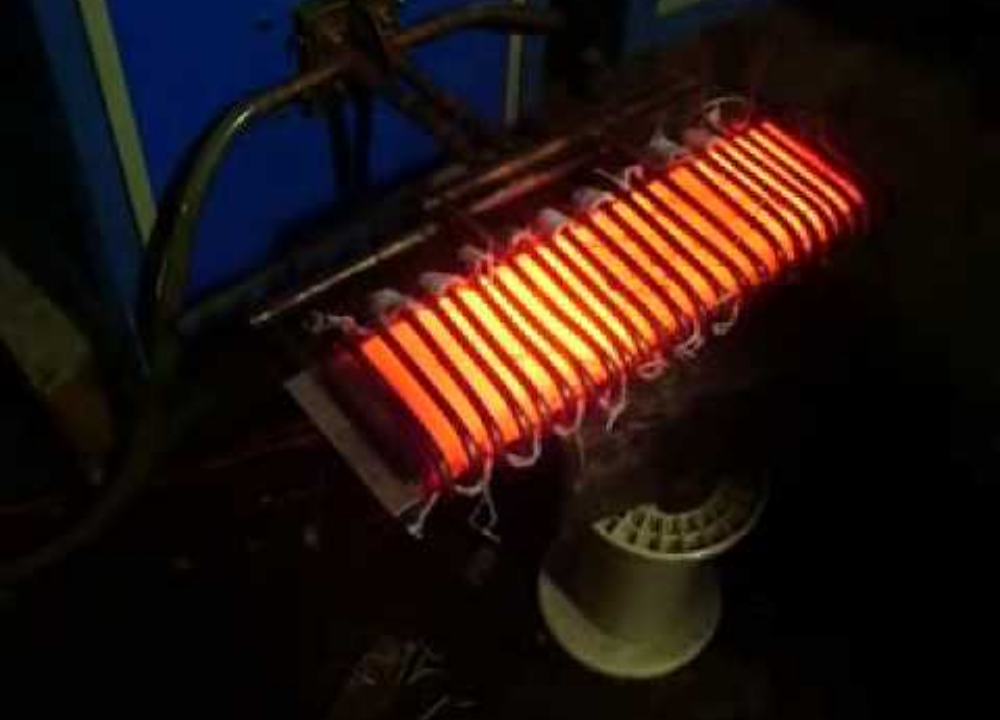

Induction Heating means to produce the alternating magnetic field through induction coil after induction heating equipment ouputs high-frequency current to make the work piece heated fast. Super Audio frequency(MTC) series: frequency 10KHz – 30KHz.

Charcteristic

WHo Are We

Malhotra Technologies was Founded in 2006, Which is Engaged in R&D, Production and sale of solid Induction heating Machine Professionally. Several senior Experts of Induction heating Equipment gathered here, WHo Initiate the Induction Heating Machines with Environmnetal Protection and Highly Effective Energy Conservation, Positively, and Diligently.

Now there are series of Products ranges from 3kw to 100kw, Including the Ultra-high/high/super-audio/Medium frequency Induction Heater. These items are developed using high-quality raw materials Secured from retailers following international Model. Special Purpose KNOW MORE 25 years professional manufacturing in Bahadurgarh and industry supplier services.

End bar heating with super audio refers to a process commonly used in industrial applications to heat the ends

Hot forming, hot forging, diathermy molding, hot rolling, hot upsetting and red stamping are all used induction heating machine.

Induction Hardening Machine

An Induction Hardening Machine is a specialized method designed for surface hardening of metal components through induction heating.

Induction Forging Machine

Induction forging Machine is a specialized system which is used to heat metal billets or work pieces to a certain temperature and then give them shape by means of flame forging.

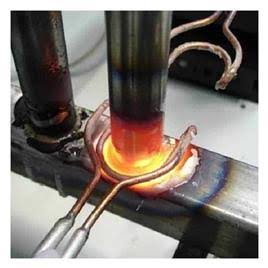

Induction Brazing Machine

An Induction Brazing Machine is specialized system that uses electromagnetic induction to heat metals, enabling the precise and reliable joining of components using a filler