INDUCTION FORGING MACHINE

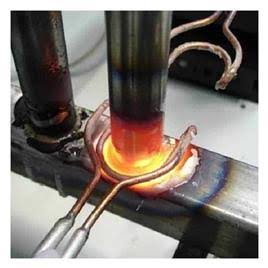

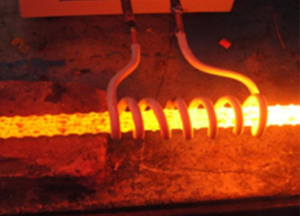

Induction forging Machine is a specialized system which is used to heat metal billets or work pieces to a certain temperature and then give them shape by means of flame forging. This instruction makes use of a heating technique, where the metal is heated by a beam without direct contact to the field of an electric magnet.

Hot Forming, hot forging, diathermy molding, hot rolling, hot upsetting and red stamping are all used induction heating machine to make the work-pieces nearly have the same temperature on surface and internal, then punching into required shape, which mainly adopt electromagnetic induction and heat conduction principle.

Malhotra Technologies is a Bahadurgarh (Haryana) based Industrial Heating Equipment. Manufacturer and Saller of Solid Induction Heating Solutions. 25 Years of Experience with Several Senior Experts of Induction Heating Equipment.

Choose the Right Induction Forging Machine

APPLICATION

Fasteners, hardware tools, automobile and motorcycle accessories, rigging, pipe fittings, twist drill, atlas, table, mould parts, standard parts, handicrafts, machinery parts, brass lock, lock, rivets and other hardware and metal accessories.

MODEL AND FREQUENCY SELECTION

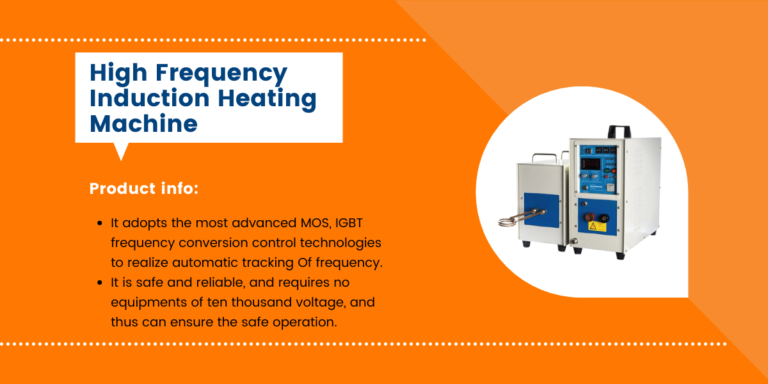

Power Determine the work-piece heating speed, frequency determines the work-piece temperature difference between inside and outside.

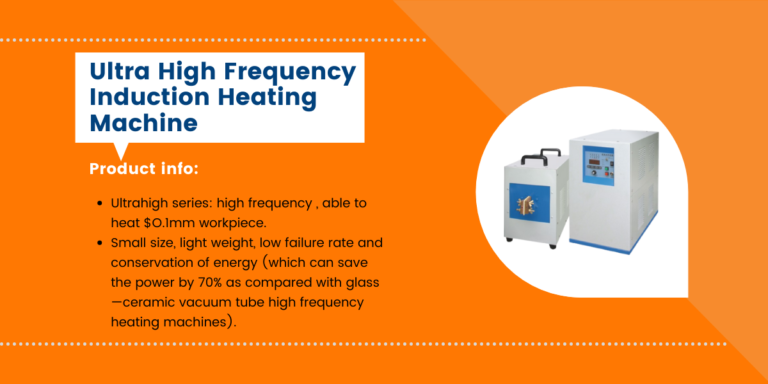

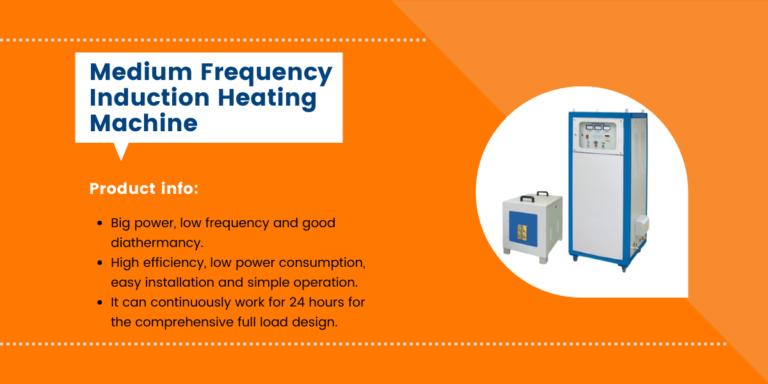

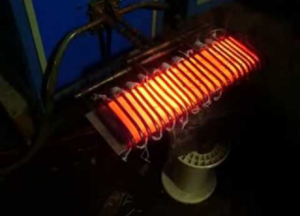

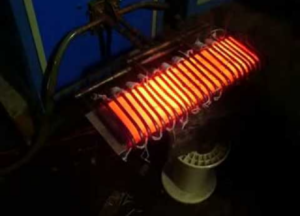

Medium frequency Induction heating Machine

A Medium frequency induction heating machines is a specialized device used for heating materials, typically metal, through electromagnetic induction. This method relies on generating an alternating magnetic field around the material to induce eddy current, which in turn generates heat due to the electrical resistance of the material.

MAIN FEATURES:

1. Big power, low frequency, and good diathermancy.

2.

High efficiency, low power consumption, easy installation, and simple operation.

3.

It can continuously work for 24 hours for the comprehensive full load design.

4.

It adopts the IGBT inverter circuit in parallel connection, which has high load adaptability.

5.

It has functions as over-voltage, over—current, over—heat, phase loss, and water shortage alarm indications as automatic control and protection.

6.

Compared with other heating modes, it can significantly promote the economic benefits, improve the quality of heated work pieces, save energy and material, alleviate labor intensity and improve the production environment.

Induction Heating Machine Applications

WE INTRODUCE OURSELVES AS THE BIGGEST SALES AND SERVICE PROVIDERS OF INDUCTION HEATING MACHINES, WHICH ARE USED FOR HARDENING, BRAZING, ANNEALING, SINTERING, FORGING, AND OTHER HEAT TREATMENT PROCESSES.

WHO ARE WE

Malhotra Technologies Established in 2007, Malhotra Technologies (Induction Master) is a reputed company that manufactures and supplies a broad assortment of (INDUCTION HEATING MACHINE) induction-hardening machines, high-frequency induction heaters, medium-frequency power heaters, UHF induction heaters, annealing machine, sintering machine, electroplating rectifiers, heat-treatment machine, and brazing machine. They also supply products like 15 series induction heaters, 25 series induction heaters, 35 series induction heaters, 70 series induction heaters, medium frequency power heaters, melting machine frequency power heaters,s and forging furnace frequency power heaters. These items are developed using high-quality raw materials procured from retailers following international norms. .

End Heating, Bar forging furnace, Bar forging, Bar heating, Bar hot forging, Bar induction Heating, Bolt Forging, Carbon Steel Forging, Copper Bar Forging, Copper Bar Heating, Copper plate Heating, End Forging, End Part Forging, Forging, Hot Forging, Nut Forging, Round Bar Forging, Round Bar Heating, Steel Bar Forging, Steel Bar Forging, Steel Billet Induction Forging, Plank diathermy, Big size Diathermy, End upsetting, Square steel diathermy, Square iron diathermy, Billet Heating, Nut Stamping, Nut Forging, Pulley Stamping, Diathermy stamping, Diathermy stuffing, Diathermy pipe bending, Diathermy complete small bar diathermy, and M.f. Forging Furnace.