Post-Weld Heat Treatment (PWHT) Machines:

Essential for Enhancing Weld Quality and Integrity

Welding is a vital process in the manufacturing and construction industry, where metals are joined together to create complex structures or machines. However, the process of applying thermal stress and microstructure to welding materials has been introduced, which in turn reduces the strength, thickness and overall strength of the material. To address these challenges, post-weld heat treatment is employed, which is an important step in ensuring that the welded joint meets the required standards for durability and performance. There are special machines designed to provide controlled heat application to the welded material at the heart of the process. In this article, we will explain in detail about the importance of peedably oochatee, the methods used by various machines, their nature and their role in improving field gunavatta. .

Understanding Post-Weld Heat Treatment (PWHT)

Before diving into the specifics of PWHT machines, it’s essential to understand what PWHT is and why it’s necessary..

What is Post-Weld Heat Treatment?

PWHT refers to the process of applying heat to a welded joint after it has been formed but before it is put into service. The primary purpose of PWHT is to relieve the residual stresses induced by welding and to refine the microstructure of the weld and heat-affected zone (HAZ). Welding introduces significant amounts of heat into the material, which can lead to the formation of cracks, distortion, or reduced mechanical properties, such as hardness and toughness. By applying controlled heating, PWHT helps:

1.

Relieve residual stresses: Welding introduces internal stresses that can cause distortion or cracking. PWHT helps in redistributing these stresses evenly throughout the material.

2.

Enhance mechanical properties: PWHT refines the grain structure of the metal, improving properties like toughness, hardness, and tensile strength.

Reduce the risk of brittle fractures: For certain materials, such as carbon steel, PWHT can reduce the risk of brittle fractures, especially at low temperatures.

3.

Prevent cracking: Some materials are prone to cracking due to the high thermal gradients and cooling rates in the welded joint. PWHT can mitigate this by allowing the material to cool more uniformly.

In many cases, PWHT is mandatory for components that will be exposed to extreme stresses or elevated temperatures, such as those used in the oil and gas, aerospace, and power generation industries..

When is PWHT Required?

This is especially important for welded joints in a material that are susceptible to breakage or damage during the sheeting process. Some of the common elements which are often found in Gujarat include:

1.

carbon and alloy steels

2.

stainless steels

3.

Nikal Aadhaarit Mishra Dhaatuen

4.

titanium alloy

The welding process is based on specific specifications, design code and its conditions. For example, piping systems in power plants, pressurized vehicles, and air machinery are often required to be specifically designed to meet safety standards..

Types of PWHT Machines

PWHT machines come in different designs and configurations, each tailored for specific applications and types of materials. The main types of PWHT machines include:.

1. Furnace-Based PWHT Machines.

Furnace-based machines are the most common and widely used equipment for conducting PWHT. These machines involve placing the welded components in an oven or furnace that provides uniform heat to the material. The type of furnace can vary, including:

A –

Batch-type furnaces: These furnaces can handle multiple components at once, making them suitable for large-scale production runs. Batch-type furnaces are designed to heat the material to a specific temperature and maintain it for a set period.

B –

Continuous furnaces: These are used when high-volume production is needed. The workpieces move through the furnace on a conveyor, allowing for continuous heat treatment of the welded joints.

Furnace-based PWHT machines offer advantages such as precise temperature control, uniform heating, and consistent results. However, they are best suited for smaller or simpler components, as loading and unloading can be time-consuming for larger or more complex geometries.

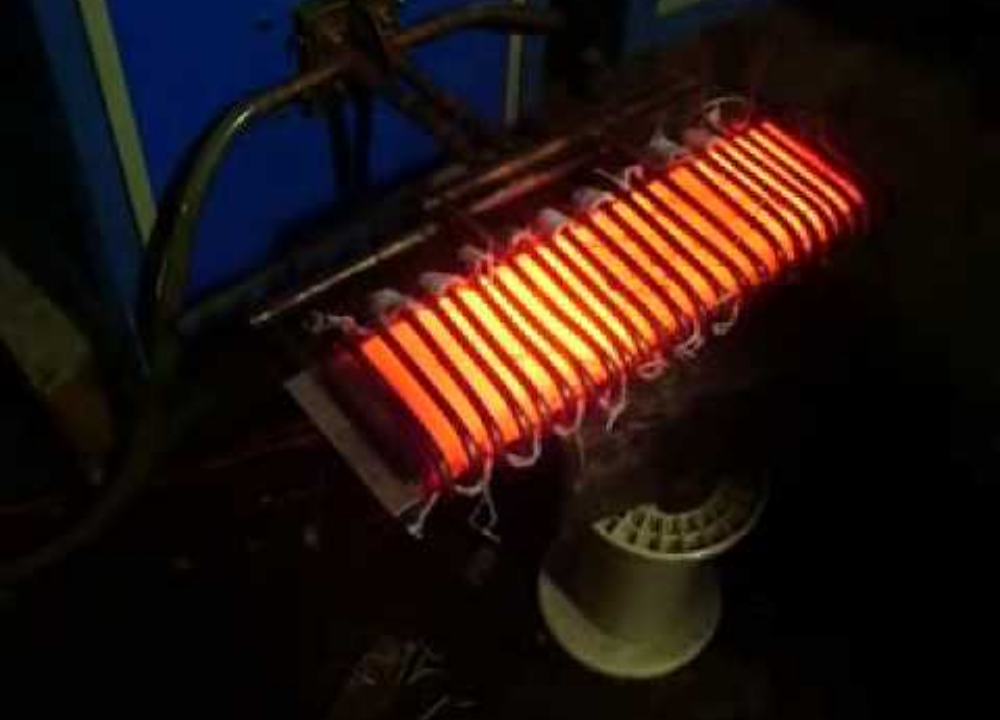

2. Induction Heating Machines

Induction heating involves using electromagnetic induction to generate heat in the material directly without the need for a physical heat source. Induction heating machines are particularly beneficial for localized PWHT, where only a specific area (such as a welded joint) needs to be treated. These machines are fast, energy-efficient, and provide precise control over temperature, making them ideal for applications requiring rapid turnaround times or precision heating.

Induction heating machines consist of a coil that surrounds the weld or HAZ. An alternating current is passed through the coil, generating heat within the material due to the induced electromagnetic field. This method is highly efficient and can be used for smaller, thinner components, as well as those that are difficult to fit into large furnace-type PWHT machines.

3. Resistance Heating Machines

Resistance heating machines use electrical resistance to generate heat. In this process, the workpiece is connected to electrodes, and electrical current is passed through the material. The resistance to the current flow causes localized heating. This heating is typically applied to the welded joint area or a specific section of the material that requires heat treatment.

Resistance heating is often used for smaller components or in situations where only the welded zone needs to undergo PWHT. The advantage of resistance heating is that it allows for rapid heating and cooling cycles, making it suitable for high-precision applications.

4. Gas-Fired Heating Machines

Gas-fired PWHT machines use a direct flame or hot gases to heat the welded workpiece. The heating is done by circulating hot gases around the workpiece or applying direct flame to the welded area. These machines are commonly used for large, bulky components that cannot easily fit into other types of PWHT machines, such as large pipelines, pressure vessels, and structural beams.

While gas-fired machines are effective at heating large components, they can sometimes result in less precise temperature control compared to furnace or induction heating machines. However, they are still widely used in industries that require high throughput and are able to tolerate slight temperature variations.

5. Portable PWHT Machines

Portable PWHT machines are designed for on-site applications, where it is not feasible to move large structures or components into a factory for heat treatment. These machines are compact, easy to transport, and allow technicians to conduct PWHT on-site, such as on large welding projects or in-field maintenance.

Portable PWHT machines often use electric or gas-powered heating systems and are typically equipped with thermal sensors to ensure that the required temperature and time parameters are met. These machines are crucial for industries like construction, offshore drilling, and shipbuilding, where equipment often needs to be heat-treated in the field.

Key Factors in Selecting a PWHT Machine

When selecting a PWHT machine, several factors need to be considered to ensure that the equipment meets the needs of the application and provides optimal performance:.

1. Material Type and Size

The type of material being welded and its size will influence the choice of the PWHT machine. For example, large carbon steel components may require a different type of machine compared to smaller stainless steel parts. Similarly, thin-walled components may need localized heating, while thicker materials might require a furnace-based approach.2. Heat Treatment Parameters

Different materials require specific heating profiles, including temperature, heating rate and adsorption time. The machine must be able to precisely control these parameters to achieve the desired results.3. Production Volume

For high-volume manufacturing, continuous furnaces or induction heating systems may be preferred for their efficiency. For smaller, one-off projects, batch-type furnaces or portable PWHT machines may be more appropriate.4. Budget and Operational Costs

The initial cost, maintenance requirements, and energy consumption of the PWHT machine must also be considered. While induction heating and resistance heating systems tend to have higher initial costs, they offer long-term energy savings and operational efficiency.

Conclusion

Post-Weld Heat Treatment (PWHT) is a critical process that significantly improves the quality and reliability of welded components. Whether using furnace-based systems, induction heating, or portable machines, PWHT machines are designed to provide precise, controlled heating to reduce stresses, improve material properties, and prevent potential failures in service. By carefully selecting the appropriate PWHT machine for the application, industries can ensure that their welded components perform optimally, enhancing the overall safety, longevity, and reliability of their structures.

In industries like oil and gas, aerospace, and manufacturing, where welded components are exposed to extreme conditions, PWHT is not just a procedural step but a crucial element of quality control. Choosing the right PWHT machine is, therefore, vital for ensuring that the welded joints meet the required mechanical and structural integrity, reducing the risk of costly failures down the road.

Investing in advanced PWHT machines, along with optimizing the heat treatment process, can significantly improve production efficiency while enhancing the overall quality of the final product..

Who Are We

Malhotra Technologies Established in 2007, Malhotra Technologies (INDUCTION MASTER) is a reputed company that manufactures and supplies a broad assortment of (INDUCTION HEATING MACHINE) induction-hardening machines, Induction Forging Machine, high-frequency induction heaters, medium-frequency power heaters, UHF induction heaters, annealing machine, sintering machine, electroplating rectifiers, heat-treatment machine, and Induction brazing machine. They also supply products like 15 series induction heaters, 25 series induction heaters, 35 series induction heaters, 70 series induction heaters, medium frequency power heaters, melting machine frequency power heaters,s and forging furnace frequency power heaters. These items are developed using high-quality raw materials procured from retailers following international norms.Special Purpose KNOW MORE Application.

PWHT Machine (FAQ)

1. Small Machines: Theses are ideal for light-duty tasks like jewelry work of small-scale manufacturing,

prices typically start from $1,000, to $5,000.

2. Medium-Sized Machines: based in industries like automotive or tool manufacturing for applications like braing, soldering and heat treating,

prices range between $5,000 to $20,000.

3. Large Industrial Machines:High-power Machines for heavy-duty applications like forging, Melting or large-scale heat treating.

These can cost $20.000 to $100,000 or more depending on the complexity and customization.