Induction heating machine is an industrial machine which is used to heat metal.

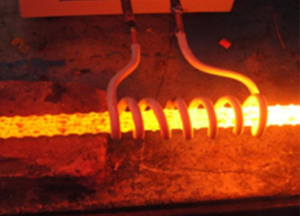

Induction heating machines are used in applications like forging, hardening, annealing, or mostly brazing.

Due to the automatic or manual features of this industrial induction heater, this machine is safe and easy to use.

High frequency, medium frequency, ultra high frequency or super audio frequency machines of induction heating machine are used in different industries. Aerospace, automotive, motorcycle parts.

It offers advantage such as precise temperature control, Minimal heat loss, and the ability to heat only the targeted area. call +91 9871756222

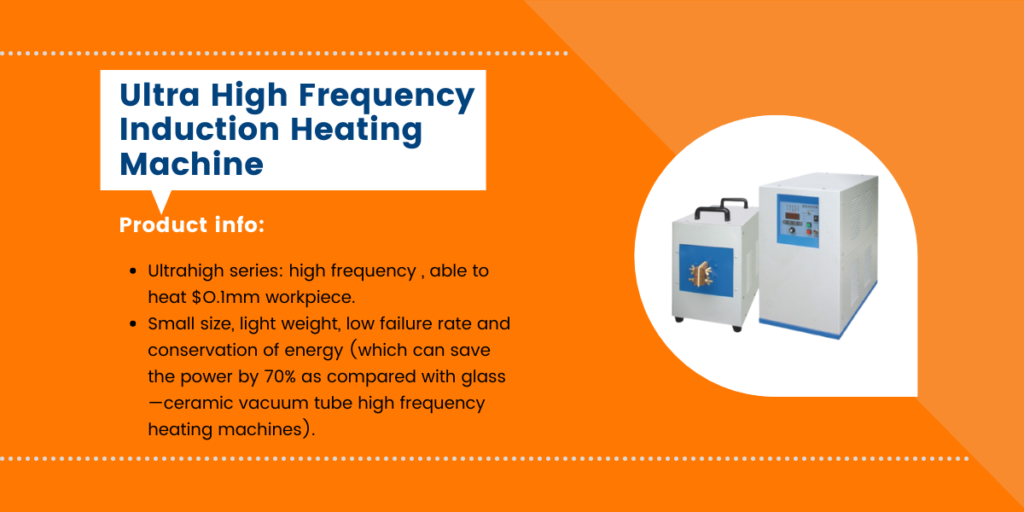

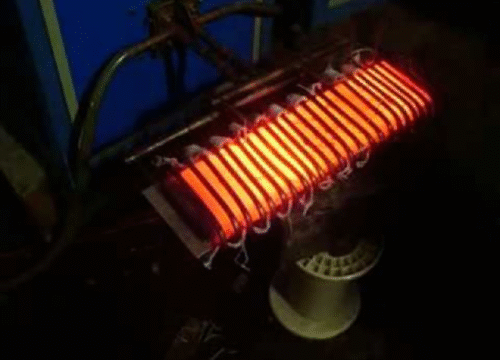

1. Ultra High Frequency Induction Heating Machines

Main Feature:

- Ultrahigh series: high frequency , able to heat$O.1mm workpiece.

- Small size, light weight, low failure rate and conservation of energy (which can save the power by 70% as compared with glass—ceramic vacuum tube high frequency heating machines).

- It can ensure the solid welding point which is pleasing and delicate in appearance, integral geometric configuration, perfect surface grain, complete crystal structure of internal metal part, limited annealing range and elimination of obvious weld knot.

- About ten types fault protection and display of over—current, over—voltage, water shortage and phase missing can provide

higher reliability and durability.

Applications

Technical Parameters:

- Model – 3kw / 6kw, 8kw / 10kw / 20kw / 30kw / 40kw / 60kw / 100kw.

- Input Voltage – single phase 220v 50/60Hz and 3 Phase 380v 50/60Hz.

- Max. Output Power – 3kw / 6kw / 8kw / 10kw / 20kw / 30kw / 40kw / 60kw / 100kw.

- Max. Input Current – 14A / 28A / 35A / 15A / 30A / 45A / 60A / 90A / 152A.

- Fluctuating Frequency – 0.2MHz to 1.1MHz and 50KHz to 500KHz.

- Pressure of Cooiling Water – 0.2MPa to 0.5MPa.

- Input Water Pressure – <40°C

- Duty Cycle – 100%

Variant:

- 3 KW Machine

- 6 KW Machine

- 8 KW Machine

- 10 KW Machine

- 20 KW Machine

- 30 KW Machine

- 40 KW Machine

- 60 KW Machine

- 100 KW Machine

Application:

- Quenching for gear

- Quenching for powder metallurgy gear

- Quenching for gardening shear

- Welding for fish hook

- Peeling off coat of paint

- Brazing for lead

- Quenching for clamp knife-edge

- Quenching for bore

- woodworking cutter brazing

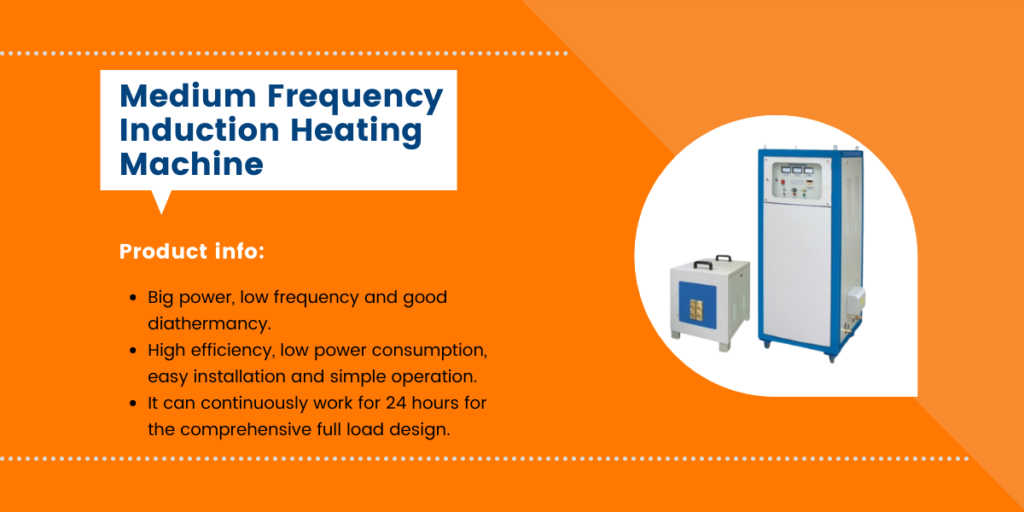

2. Medium Frequency Induction Heating Machine

Induction Heating Machine

Main Feature:

- Big power, low frequency and good diathermancy.

- High efficiency, low power consumption, easy installation and simple operation.

- It can continuously work for 24 hours for the comprehensive full load design.

- It adopts the IGBT inverter circuit in parallel connection, which has high load adaptability.

- It has functions as over-voltage, over—current, over—heat, phase loss and water shortage alarm indications as

automatic control and protection. - Compared with other heating modes, it can significantly promote the economic benefits, improve the quality of heated work pieces, save the energy and material, alleviate labor intensity and improve the production environment.

Applications

Technical Parameters:

- Model – 15kw / 25kw / 35kw / 45kw / 70kw / 90kw / 90kw / 110kw / 160kw / 260kw / 360kw / 600kw.

- Input Voltage – 3 Phase 380v 50/60Hz.

- Max. Output Power – 15kw / 25kw / 35kw / 45kw/ 70kw / 90kw / 90kw / 110kw / 160kw / 260kw / 360kw / 600kw.

- Fluctuating Frequency – 0.5 to 20.

- Pressure of Cooiling Water – 0.2MPa to 0.8MPa.

- Input Water Pressure – <40°C

Variant:

- 15 KW Machine

- 25 KW Machine

- 35 KW Machine

- 45 KW Machine

- 70 KW Machine

- 90 KW Machine

- 110 KW Machine

- 160 KW Machine

- 260 KW Machine

- 360 KW Machine

- 600 KW Machine

Application:

- Medium frequency forging

- Heating for iron bar

- Aluminium melting

- Powder Metallurgy sintering

- Medium frequency melting furnace

- Heating for medium frequency

- Melting

- Heating steel products

- Bar end heating for the pneumatic feeding

- Bar end heating for the manual feeding

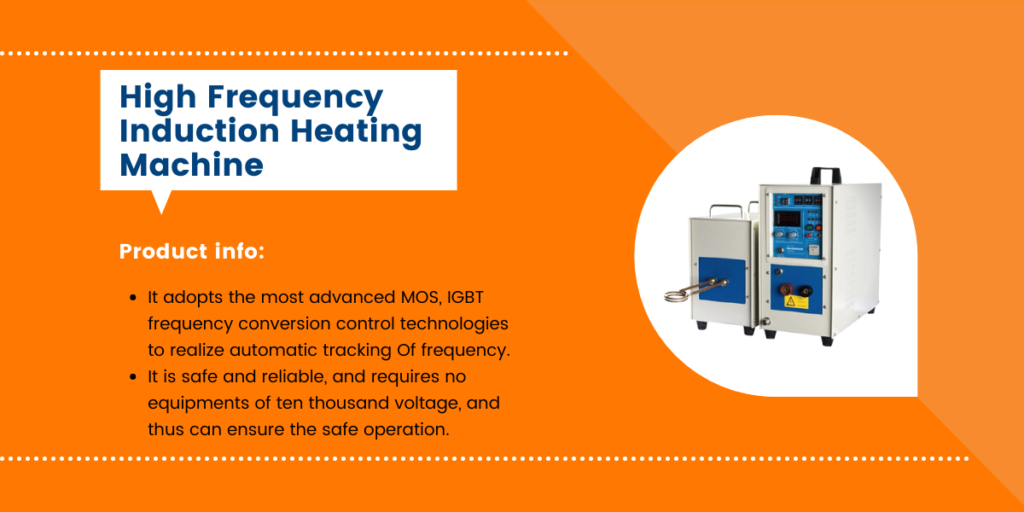

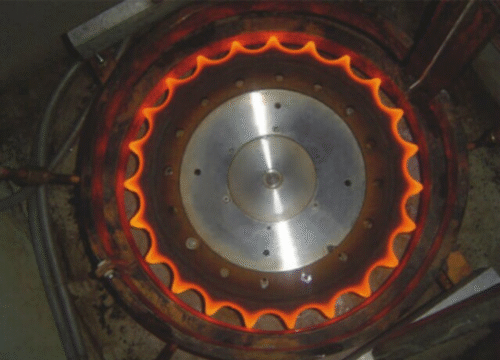

3. High Frequency Induction Heating Machine

Induction Heating Machine

Main Feature:

- It adopts the most advanced MOS, IGBT frequency conversion control technologies to realize automatic tracking Of frequency.

- It has the constant current and power control function, which can significantly optimize metal heating process, realize the high efficient and fast heating and bring into play the superior performance of the products.

- About ten types fault protection and display of over—current, over—voltage, water shortage and phase missing can provide higher reliability and durability.

- It is safe and reliable, and requires no equipments of ten thousand voltage, and thus can ensure the safe operation.

- It is available for infrared temperature measurement, which can realize the automatic control of temperature, improve the heating performance and simplify the manual operation.

Applications

Technical Parameters:

- Model – 5kw / 15kw / 25kw / 30kw / 40kw / 50kw / 60kw / 80kw / 120kw.

- Input Voltage – single phase 220v 50/60Hz and 3 Phase 380v 50/60Hz.

- Max. Output Power – 5kw / 15kw / 25kw / 30kw / 40kw / 50kw / 60kw / 80kw / 120kw.

- Fluctuating Frequency – 30 to 250.

- Pressure of Cooiling Water – 0.2MPa to 0.6MPa.

- Input Water Pressure – <40°C

Variant:

- 5 KW Machine

- 15 KW Machine

- 25 KW Machine

- 30 KW Machine

- 40 KW Machine

- 50 KW Machine

- 60 KW Machine

- 80 KW Machine

- 120 KW Machine

Application:

- Heating for the copper or steel plate

- Rotor hot cooperation

- Annealing for steel products

- Hot forging for watchcase

- Heating for cartridge case

- Radiator hot cooperate

- Brazing switched for contract

- Brazing for aluminum for sealing

- Brazing for cutting tools

4. Super Audio Frequency Induction Heating Machine

Induction Heating Machine

Main Feature:

- This equipment adopts the IGBT inverter circuit in parallel connection, which has is high load adaptability.

- The comprehensive full load design is available for 24—hour continuous operation.

- The digital phase locked realizes following frequency automatically.

- Design in modules. It is installed facility and use conveniently without debugging.

- The perfect protection function, insuring the reliability and easily maintaining of the equipments.

- The technique of converting frequency by resonance promotes efficiency of whole equipment by over 95%.

- Economy and environment protection, it can replace of then gas/coal/electronic tube induction heating machine.

Technical Parameters:

- Model – 30kw / 50kw / 60kw / 80kw / 120kw / 160kw / 200kw.

- Input Voltage – 3 Phase 380v 50/60Hz.

- Max. Output Power – 30kw / 50kw / 60kw / 80kw / 120kw / 160kw / 200kw.

- Fluctuating Frequency – 10 to 30.

- Pressure of Cooiling Water – 0.2MPa to 0.6MPa.

- Input Water Pressure – <40°C

Variant:

- 30 KW Machine

- 50 KW Machine

- 60 KW Machine

- 80 KW Machine

- 120 KW Machine

- 160 KW Machine

- 200 KW Machine

Application:

- Hot forging for standard parts

- Hot forging for copper stick

- Annealing for kitchen tools

- Hot forging for pontil

- Bending

- Annealing for stainless steel pot

- Nut Forging

INDUCTION HEATING MACHINE (FAQ)

Usage :-

>Thermoforming (hot-forging, heat penetration formation, hot rolling)

>Brazing ( brazing for cutting tools, brazing for auto parts, brazing for aluminum foil sealing)

>Heat Treatment (quenching, annealing, hardening, etc.)

>Melting (melting for gold, copper, stainless steel and other metal materials)

An induction heating machine generates a high-frequency alternating current that passes through a coil. This creates a magnetic field around the coil. When a conductive material is placed inside this magnetic field, the eddy currents generated in the material produce heat..

Main Component :->Power Supply

>A coil (Inductor)

>Cooling water system

>Control Unit.

In Haryana, induction heating machines are widely available, especially in industrial hubs like Faridabad, Gurgaon, Manesar, and Sonipat. These machines serve industries such as automotive, metalworking, and manufacturing. Key types include high-frequency, medium-frequency, low-frequency, and portable induction heaters.

Notable suppliers include companies like Malhotra Technologies, offering various customized solutions. When purchasing, consider after-sales support, customization options, and energy efficiency, which are crucial for Haryana’s industrial needs.

2. Low power consumption: it can be used to heat various metal parts (can replace the removable induction coil for different shape).

3. High effectiveness: it is applicable to control the temperature for heating work pieces that it has such features as uniform heating, fast warming and limited oxic horizon.

4. Widely applicable: it can be used to heat various metal parts (can replace the removable induction coil for different shape)

5. Small size and light weight: It has a weight of only several dozens of KGS and with small size that can save the space of the workshop and can be moved conveniently.

6. Easy operation: CNC design, easy installation and simple operation that you can learn to operate it with several minutes. It can be started to perform heating operation on condition that water and power supply is available.

7. Environmental protection: it is free of any noise, exhaust gas and dust that can provide a much bette environment for the workers than the conventional heating with such fuels as coal, gases, and oil.