What is High Frequency induction heating machine

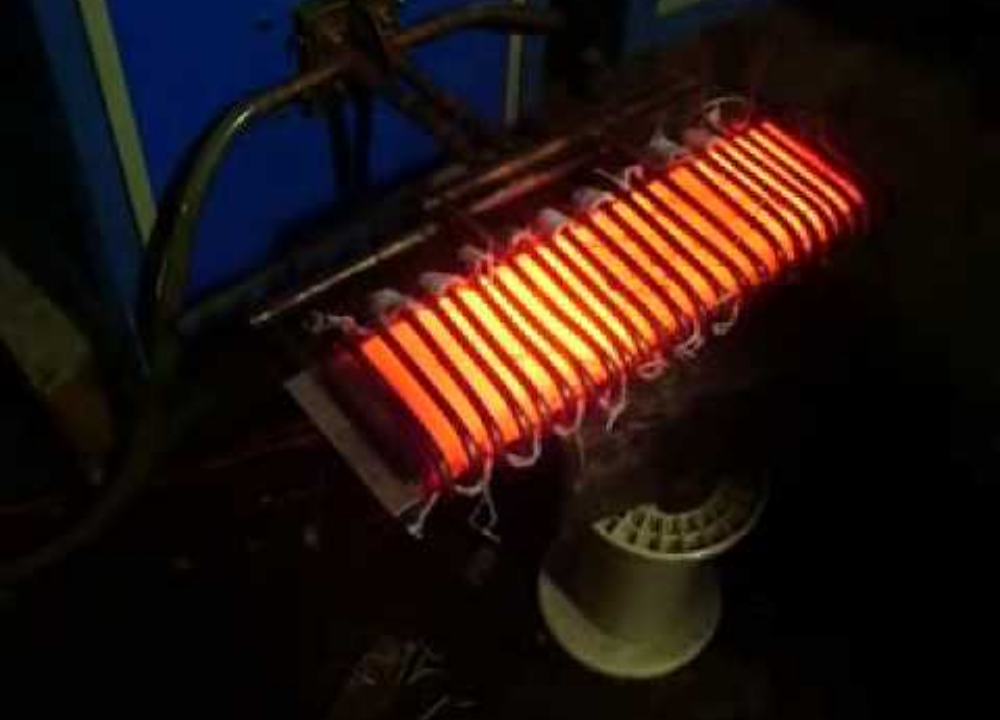

A High-frequency induction heating machine uses a magnetic field to induce current in a conductve material, producing heat. unlike traditional methods, induction heating is contactless, fast and highly targeted.

The key components include:

_ Induction Coil : Generates the magnetic field.

_ Power source: Supplies the required high-frequency current.

_ Cooling System: Prevents overheating of the equipment

Application of high frequency heating machine

1. Metal Hardening:

Induction heating is used extensively in the automotive, aerospace and tool making industries for surface hardening, providing a wear-resistant layer while maintaining a tough core.

2. Soldering and Brazing:

High-frequency machines excel at joining metals with precision, ensuring strong and clean bonds in electronics, plumbing and HVAC applications.

3. Annealing:

They offer localized heating for processes like annealing wires, reducing brittleness, and enhancing material flexibility.

4. Shrink Fitting:

Induction heating simplifies the assembly of components by precisely expanding or contracting parts for a seamless fit.

5. Forging and Melting:

These machines deliver the high temperatures needed for forging and melting metals with minimal energy loss..

Industries Benefiting from Induction Heating Technology

1. Automotive: Gear hardening, crankshaft tempering.

2.

Electronics: Circuit board soldering.

3.

Energy: Pipe welding and repair.

4.

Manufacturing: Tool and die production.

.

Advantage of high frequency heating machine

1. Efficiency: Converts up to 90% of the energy into heat.

2.

Precision: Targets specific areas without affecting surrounding materials.

3.

Speed: Heats materials rapidly, reducing cycle times.

4.

Safety: Eliminates open flames and toxic fumes.

5.

Environmental Impact: Offers a cleaner alternative to traditional heating methods..

Why choose high frequency heating machine

Investing in a high-frequency induction heating machine ensures reliability, stability, and adaptability in a variety of industrial applications. With increasing emphasis on sustainability and efficiency, these machines are paving the way for smart manufacturing processes..

Who Are We

Malhotra Technologies Established in 2007, Malhotra Technologies (INDUCTION MASTER) is a reputed company that manufactures and supplies a broad assortment of (INDUCTION HEATING MACHINE) induction-hardening machines,Induction Forging Machine, high-frequency induction heaters, medium-frequency power heaters, UHF induction heaters, annealing machine, sintering machine, electroplating rectifiers, heat-treatment machine, and brazing machine. They also supply products like 15 series induction heaters, 25 series induction heaters, 35 series induction heaters, 70 series induction heaters, medium frequency power heaters, melting machine frequency power heaters,s and forging furnace frequency power heaters. These items are developed using high-quality raw materials procured from retailers following international norms.Special Purpose KNOW MORE.

High Frequency Heating Machien (FAQ)

TYPE OF INDUCTION HEATING MACHINE

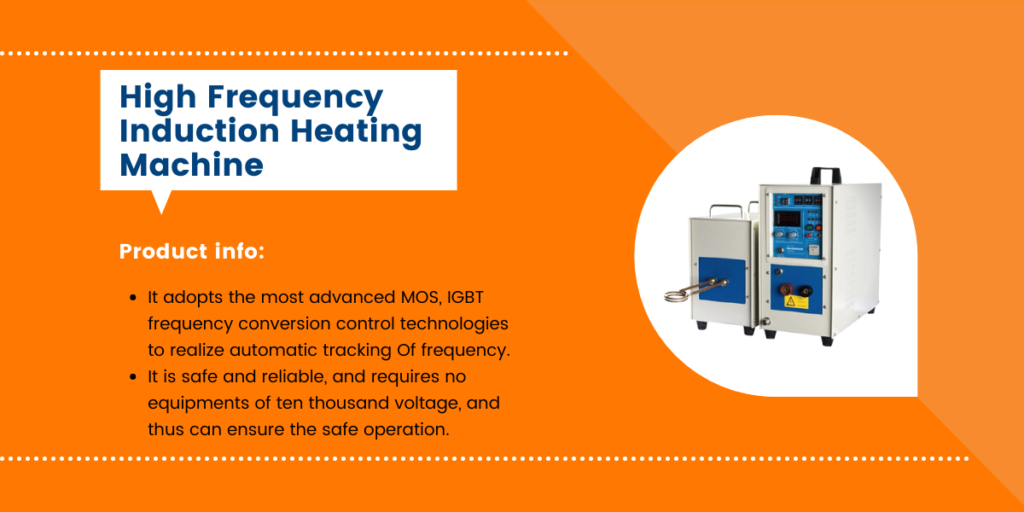

1. HIGH FREQUENCY INDUCTION HEATING MACHINE

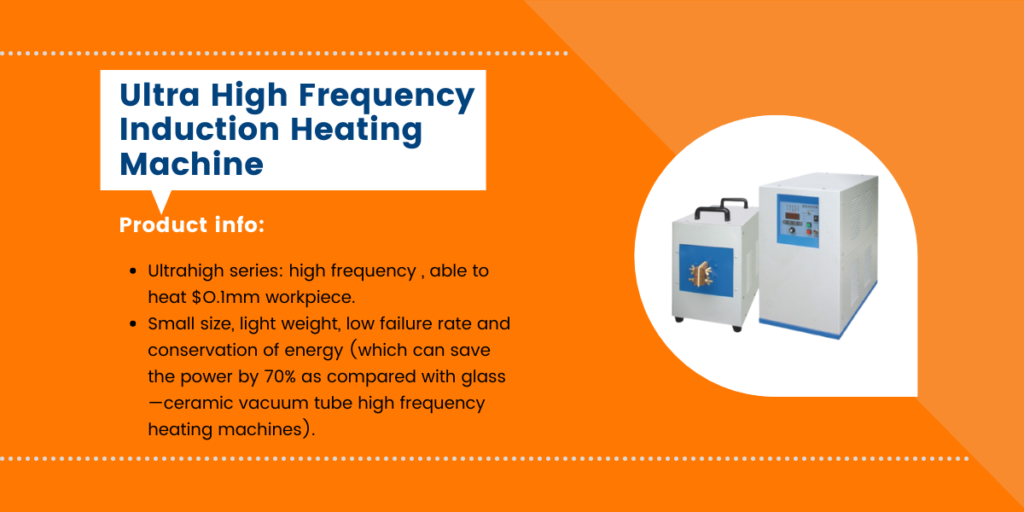

2. ULTRA HIGH FREQUENCY INDUCTION HEATING MACHINE

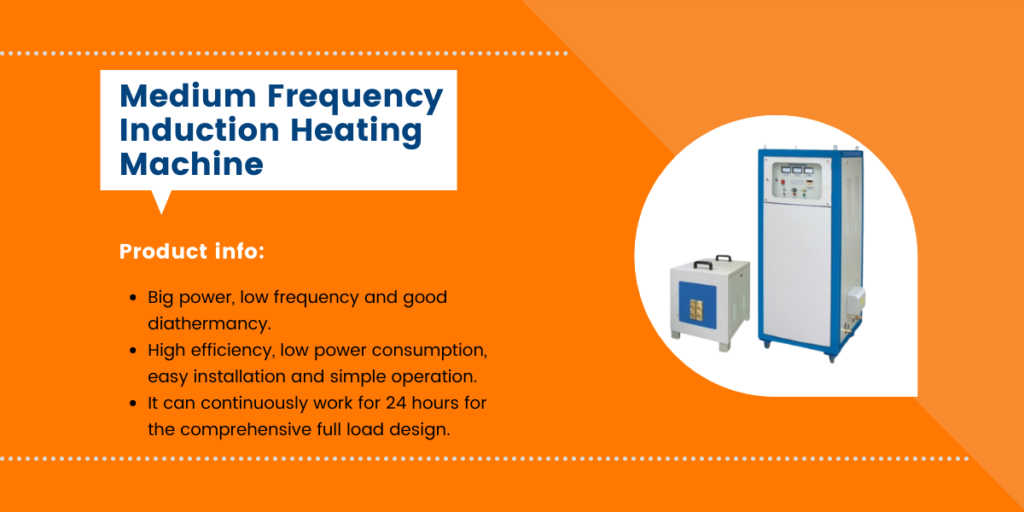

2. MEDIUM FREQUENCY INDUCTION HEATING MACHINE

4. SUPER- AUDIO FREQUENCY INDUCTION HEATING MACHINE

Basic models: Around ₹1.5 lakh to ₹2.5 lakh.

Mid-range models: Around ₹3 lakh to ₹4 lakh.

High-end models: Can go up to ₹20 lakh or more.

Would you like more detailed information on specific models or features