We Introduce to Product ' Applications

Induction Heating Machine

INDUCTION HEATING APPLICATION

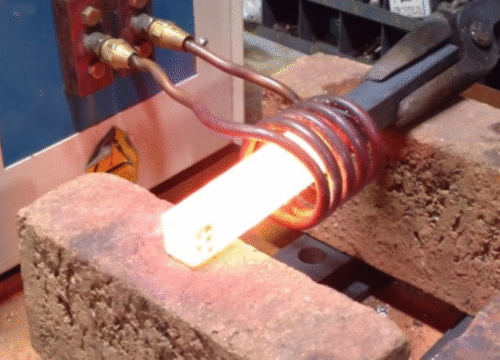

Induction Heating means to produce the alternating magnetic field through induction coil after induction-heating equipment outputs high-frequency current to make the work piece heated quickly. Induction Heating machine use large hardening work piece, tempering, cooling, solid design, high-frequency induction heating machine full automatic. (Induction Master)

1. Hardening : Strengthening metals by heating and cooling them quickly.

2. Solder and Brazing : Braze metal parts with a filler material, often used in electronics and plumbing.

3. Melting : Efficiently melting metals for casting or recycling , commonly used in foundries.

4. Forging : Heating metal to make it malleable for shaping through mechanical force.

5. Surface Hardening : Improving the wear resistance of machine components by heating only the surface layer.

6. Heat Treatment : Altering the properties of metals to improve strenth, Ductility, or toughness.

7. Cooking ; In some Kitchen appliances, induction heating is used for cooking due to its speed and efficiency.

8. Preheating : Preparing metal components for welding or further processing by bringing them to a specific temperature

Induction Heating Application

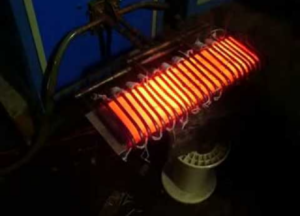

1. Medium Frequency Induction Heating Machine

Application Examples

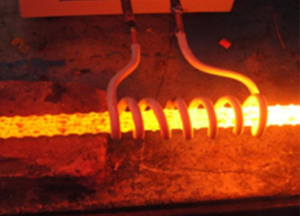

Heating For Iron Bar

Heating For Medium Frequency

Melting

2. Super Audio Frequency Induction Heating Machine

Application Examples

3. High Frequency Induction Heating Machine

Application Examples

Heating For Cartridge Case

Heating For Copper Or Steel Plate

Brazing For Cutting Tools

4. Ultra High Frequency Induction Heating Machine

Application Examples

Welding For Fish Hook

PCB Soldering

Quenching For Gardening Shear

(SAIHM) End Bar Heating

The End bar heating process is an Industrial Technique used to Selectively heat the ends of metal bars, preparing them for processes such as forging, bending, upsetting, or joining. This Targeted heating is Particularly beneficial for Applications requiring consistent heating with minimal impact on the surrounding material.

- 100% Free Consultation

Frequently Asked Questions

We are the manufacturer and we have more than 15 years experience in laser cutting & engraving equipment. Our service after sales is good, we know how to solve the problems encountered in the use of the machine.

Induction Heating Machine (FAQ)

1. Hardening : Strengthening metals by heating and cooling them quickly.

2. Solder and Brazing : Braze metal parts with a filler material, often used in electronics and plumbing.

3. Melting : Efficiently melting metals for casting or recycling , commonly used in foundries.

4. Forging : Heating metal to make it malleable for shaping through mechanical force.

5. Surface Hardening : Improving the wear resistance of machine components by heating only the surface layer.

6. Heat Treatment : Altering the properties of metals to improve strenth, Ductility, or toughness.

7. Cooking ; In some Kitchen appliances, induction heating is used for cooking due to its speed and efficiency.

8. Preheating : Preparing metal components for welding or further processing by bringing them to a specific temperature

>low-end models : $2,000 to $5,000

>Mid-range models: $5,000 to $10,000

>High-end or industrial-grade models: $10,000 to $20,000

If you are looking for an exact price. it’s best to contact suppliers or manufactures for a detailed quote based on your specific needs: like (Malhotra Technologies)15 years old industry